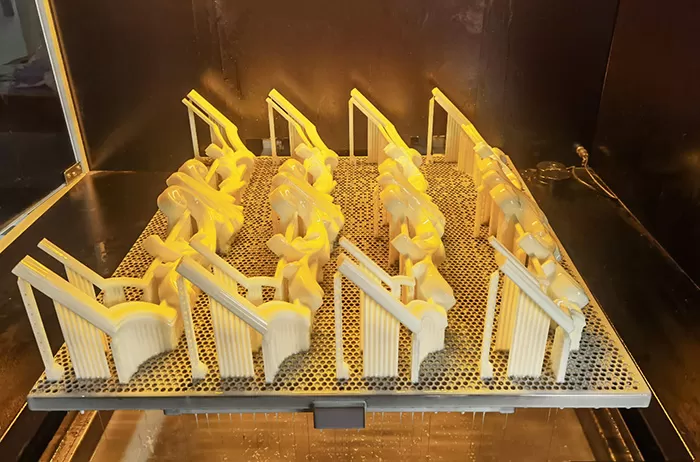

HRD 3D printing prototype

3D printing is a term used to describe additive manufacturing, which includes a series of rapid prototyping techniques for manufacturing parts by stacking multiple layers of materials. 3D printing prototypes are a fast, simple, and cost-effective way to transform designs into products.

SLA 3D Print |

SLS 3D Print |

Types of 3D Printing | |

|---|---|

What is SLA 3D printing? SLA printing uses ultraviolet lasers to form thousands of thin layers on the surface of liquid thermosetting resin until the final component is formed. SLA printing can achieve a wide range of material selection, extremely high feature resolution, and high-quality surface treatment. | What is SLS 3D printing? SLS printing utilizes high-power optical lasers to fuse fine powder particles layer by layer, thereby producing complex and durable geometric parts. SLS printing uses filled nylon material to manufacture sturdy parts, suitable for the production of functional prototypes and end use parts. |

How does SLA 3D printing work?

| How does SLS 3D printing work?

|

Shorten delivery time.:

Parts can usually be shipped out in just a few days, accelerating design iterations and time to market.

Build complex shapes:

Allowing the creation of more complex geometries and precise details of parts without increasing costs.

Reduce manufacturing costs:

Reduce production costs by eliminating the need for tools and reducing labor.

Get Started

3d printing

3d printing is a quick and cost-saving approach to realize your dream design. At Huaruida, we provide SLA (stereolithography) and SLS (Selective Laser Sintering) 3D printing services.

HOW CAN WE HELP YOU?

Because in the professional so confident.Start by getting in touch so we can help determine the right solution for your needs. Reach out to us today!

Choose 3D printing or CNC machining

Which is more suitable for your prototype and production, 3D printing or CNC machining?

4

STEPS

HuaRuiDa 3d printing Advantages

01

Fast Quotation

On work days, you will receive our offer within 24 hours.

02

100% Quality Inspection

Parts are 100% inspected before packaging

03

Low Cost

Given the advantage of in-house cnc machining and full industrial supply chain, cost can be controlled from material procurement to final parts delivery

3d printing Cooperation Flow

01

Quotation & project Discussion

Once your drawings and project requirements are received, quotation will be provided within 24 hours.

02

Contract Confirmation

This process is to confirm quotation, such as quantity, material, surface treatments, etc. If everything ok, contract can be signed.

03

Deposit Payment

30% deposit is needed for production arrangements.

04

Production

Material will be purchased and examined, meanwhile our engineers get ready for cnc programming, machine set-up, fixture and cutting tools preparation, etc. In the whole production process, you will receive photos or videos for parts production.

05

Quality Inspection

From production to post processing, our production and quality inspection team uses micrometer, CMM, Rockwell hardness tester, etc to make sure parts compliant to drawings and requirements.

06

Balance Payment

70% balance payment is needed before delivery.

07

Packaging & Delivery

Parts will be safely packed and delivered as required. Tracking number will be sent to you once available.

IS THERE ANYTHING WE CAN HELP WITH

If you have any questions about our services, please feel free to contact us at any time

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.