Apr.

16, 2025

Contents

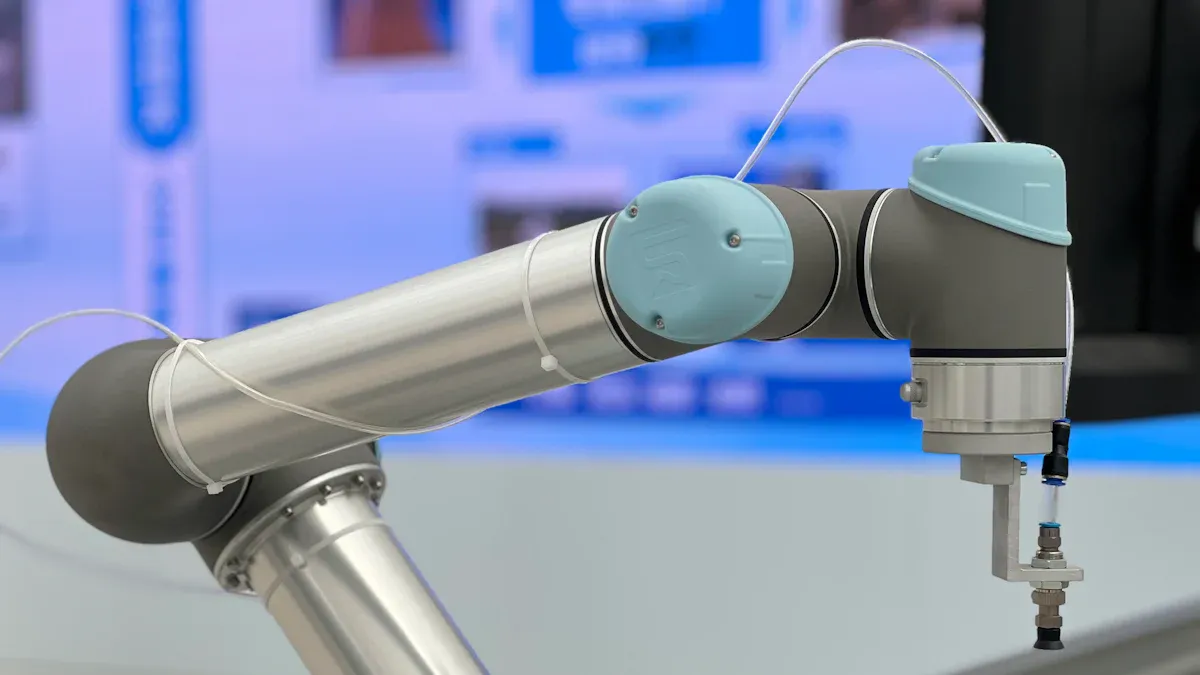

The Role of Custom Machined Parts in Industrial Robots

The Importance of Custom Machined Parts in Industrial Robots

Examples of Custom Machined Parts in Robotics

Benefits of Custom Machined Parts in Industrial Robots

Advancements in Machining Technologies for Robotics

Custom machined parts are very important for industrial robots. These parts help robots work with great accuracy and efficiency. For example, a user of the Meca500 robotic arm saw production increase by 500 percent because of these custom machined parts. Making parts to fit exact needs improves how flexible and dependable robots are. This accuracy helps robots do detailed jobs easily, even in tough conditions. Adding custom machined parts not only improves how robots work but also helps create new ideas in robotics.

Industrial robots need to work with great accuracy and speed. This is possible because of well-made, precise parts. These parts fit perfectly in robots, helping them run smoothly and avoid mistakes. For example, improving steps like joining and finishing during production makes robots work better. When all parts work well together, robots perform their best, even in tough jobs.

Custom machined parts are very important for this. They are made to exact needs, helping robots handle hard tasks. Whether building tiny electronics or welding big pieces, these parts give steady results. By focusing on accuracy, robots can work better and get more done.

Different industries need robots to do special jobs. Custom machined parts help robots adjust to these needs. In medicine, for example, these parts make tools, implants, and machines for tests. A well-made implant fits perfectly, which helps patients heal faster.

Custom parts also help create new ideas in many fields. As Elimold explains, these parts make robots more flexible, from testing ideas to full production. Tools like CNC machining make it easy to get custom parts quickly. This lets robots be made for specific jobs, like building cars or packing food. Using these parts helps solve problems and makes work more efficient.

Robotic arms need precise joints to move accurately. These joints, made with custom machined parts, allow smooth and controlled movements. For example, robotic arms in chip-making can be accurate up to ±0.02 mm. This level of precision is very important for tasks like laser cutting, where tiny mistakes can ruin the work.

Custom machined parts also improve servo motors in robotic joints. These motors help robots move with extreme accuracy, repeating tasks with ±0.01 mm precision. Robots can do the same job over and over without errors. Using strong materials like titanium and stainless steel makes these parts last longer under stress.

Important features of these parts include:

Precision Tolerances: As small as ±2 to ±5 microns (0.002 mm to 0.005 mm).

Material Selection: Common materials include Aluminum (6061, 7075), Titanium (Grade 5), and plastics like PEEK.

Surface Finishing: Smoothness below 0.2 µm for better performance.

These features help robotic arms work well, even in tough conditions.

End effectors are tools at the end of robotic arms. They are made to handle objects during tasks. Custom machined parts make end effectors fit specific jobs. For example, robots in factories deal with items of different shapes, sizes, and weights. Standard tools may not work for all these needs.

Custom designs solve these problems:

Gripping Delicate Items: Custom tools handle fragile objects without breaking them.

Manipulating Heavy Components: Special tools lift and move big or heavy items safely.

Improved Efficiency: Custom tools save time by reducing tool changes.

These tools make robots more useful in factories. Whether welding, assembling, or packing, custom machined partshelp end effectors work better.

Sensors help robots measure and adjust to their surroundings. Custom machined parts improve how sensors fit and work. For example, a robot’s accuracy improved from ±2 mm to less than 0.1 mm with custom sensors. Another machine’s accuracy went from 8 mm to just 0.13 mm.

Most robot errors happen in their joints. Custom machined parts reduce these errors by making sensors fit perfectly. Strong materials like POM and PEEK are used to make durable sensor housings.

Custom sensors help robots work more precisely. This is very important in industries like aerospace and healthcare, where small mistakes can cause big problems. Custom machined parts ensure sensors meet top standards like ISO 9001 and AS9100.

Industrial robots need to work with great precision every time. Custom machined parts help robots achieve this by improving their accuracy. These parts are made using special machines that cut with tiny errors. This precision lets robots repeat tasks perfectly, which is very important in industries like car-making and electronics.

These parts also make production more uniform. Factories can create thousands of identical pieces, ensuring robots work the same way every time. CNC machines are key because they make sure parts from different batches are exactly alike. This consistency helps keep quality high and operations reliable.

Key Benefits of Precision Machining:

Tiny errors for better accuracy.

Same results in every production batch.

Works well in many industries.

Using custom machined parts helps robots work accurately and repeat tasks without mistakes.

Robots need to last a long time to be useful. Custom machined parts make robots stronger and less likely to break. For example, CNC-made parts can handle tough conditions, lowering the chances of failure.

One factory switched to PPS CNC parts instead of regular metal ones. This change made their machines last longer. PPS parts are strong and resist damage, cutting down on repair costs and downtime. This shows how custom machined parts make robots more reliable over time.

Advantages of Durable Custom Parts:

Robots last longer.

Fewer repairs needed due to strong materials.

Work well in tough environments.

Choosing durable custom machined parts keeps robots running longer and reduces interruptions.

Different industries need robots to do special jobs. Custom machined parts let robots adjust to these needs. For example, 3D printing can make unique designs cheaply. This helps robots do specific tasks in fields like healthcare, space, or factories.

In molding, companies like DeKalb Molded Plastics use robots with custom machined parts. This change reduced heavy lifting by workers, making work safer and faster. In industries like furniture and clothing, custom parts allow for personalized designs while keeping production efficient.

Examples of Adaptation:

Special designs for unique tasks using 3D printing.

Safer and faster work in factories.

Custom solutions for consumer products.

With custom machined parts, robots can handle different jobs and meet industry needs effectively

CNC machining has changed how robotic parts are made. It offers unmatched accuracy and speed. These machines can make parts with tolerances as small as ±0.0001 inches. This ensures every piece fits perfectly. Robots need this precision to work reliably and consistently. CNC machining also creates complex designs in one step, saving time and effort.

Another great thing about CNC machining is its material flexibility. It works with aluminum, titanium, and special plastics. This means you can pick the best material for your robot's job. By combining accuracy, complexity, and material options, CNC machining helps improve robotic technology.

Key Benefits of CNC Machining:

Very precise parts with tight tolerances.

Quick production of detailed designs.

Works with many types of materials.

Additive manufacturing, also called 3D printing, has changed how custom robot parts are made. It allows for creating shapes that older methods can't make. For example, studies show it improves performance and comfort in many uses. In robotics, these benefits mean better designs and improved functions.

This method is also great for making custom parts. You can design pieces for specific tasks, like lightweight grippers or detailed sensor covers. This helps robots handle unique challenges in fields like healthcare and space. Additive manufacturing also wastes less material, making it a greener choice for making robot parts.

Advantages of Additive Manufacturing:

Makes complex shapes for better performance.

Custom parts for special tasks.

Less waste, helping the environment.

New materials have made robotic parts much better. Soft materials like silicone are used in gentle robots for surgery or farming. Bio-inspired actuators copy natural movements, making robots more efficient and precise.

Advanced materials like shape-memory alloys and piezoelectric materials also improve robots. These materials adjust to changes, making robots more flexible. Energy-saving materials have led to low-power actuators, which are better for the planet. Smaller materials have helped create tiny robots and wearable devices.

Notable Material Innovations:

Silicone for soft robots in delicate jobs.

Shape-memory alloys for flexible parts.

Eco-friendly materials for greener robots.

Custom machined parts are key to making industrial robots successful. They help robots work precisely, last longer, and adapt to different tasks. For instance, robots can work with tolerances as small as ±0.0002 inches. This improves how fast and cost-effective they are. The table below shows important performance details:

Metric Description Precision Works with tolerances of ±0.0002 inches for steady quality. Efficiency Speeds up production by automating tasks and running nonstop. Cost Reduction Cuts labor costs and saves materials, making work more productive. Enhanced Safety Handles dangerous jobs, keeping workers safe from harm.

New machining methods keep improving robots, helping them become smarter and more efficient.

Custom machined parts are special pieces made for robots. They are designed to fit perfectly and help robots work better. These parts include joints, tools, and sensor covers made for specific jobs.

These parts make robots more accurate by fitting tightly and aligning well. This helps robots do tasks exactly right every time. For example, custom joints let robotic arms move as precisely as ±0.01 mm, which is very important in making electronics or airplanes.

Custom parts are made from strong materials like titanium or aluminum. These materials handle tough conditions and last longer. For instance, PPS CNC parts are stronger than regular metals, so robots need fewer repairs and work longer.

Yes, they can save money. Custom parts help robots work faster and with fewer mistakes. This reduces labor costs and downtime. Also, methods like CNC and 3D printing waste less material, making production cheaper.

Many industries use these parts, like healthcare, car-making, and aerospace. In healthcare, robots with custom parts help in precise surgeries. In factories, they do jobs like welding and packing, making work safer and faster.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.