Apr.

23, 2025

Contents

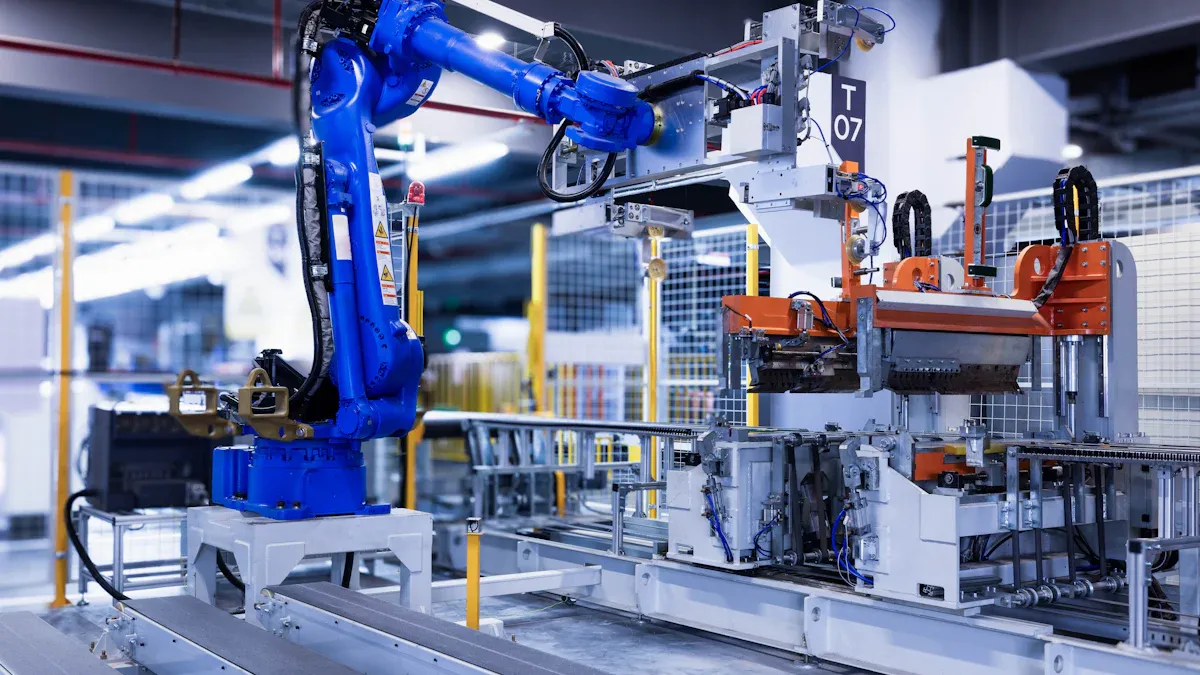

Custom Machined Solutions for Assembly Issues in a 6-Axis Industrial Robot Project

Common Assembly Issues in 6-Axis Industrial Robots

Benefits of Custom Machined Solutions

Examples of Custom Machined Solutions

Implementing Custom Machined Solutions

Custom Machined Solutions are essential for resolving issues in 6-axis robots. These robots frequently encounter problems such as misaligned parts or incompatible materials. Even minor errors in robot construction can lead to significant complications down the line. Experts assert that robots operate more efficiently and with greater accuracy when components fit seamlessly. Custom machining provides tailored parts that align perfectly, enhancing the overall performance of robots.

Misalignment is a frequent problem in building 6-axis robots. Even small alignment mistakes can affect movement and accuracy. This often happens because parts don’t match perfectly or assembly errors occur. Misaligned parts cause more wear and tear, shortening the robot’s life. Custom Machined Solutions fix this by making parts that fit exactly. These custom parts ensure proper alignment, boosting the robot’s precision and dependability.

The materials used in robots are very important. If materials aren’t strong or durable enough, the robot won’t work well. Problems like rust, early damage, or breaking can happen. Custom machining solves this by checking and testing materials before use. This ensures materials are strong and meet all requirements. Testing custom materials and shapes also helps meet ISO standards before making more parts.

Standard parts don’t always work for complex robots. Making big parts with regular tools takes up space and costs a lot. This makes it harder to produce small batches efficiently. Custom Machined Solutions solve this by using special methods to make parts. These methods allow creating custom parts without needing large spaces or standard part limits. This helps robots get the exact parts they need.

Custom Machined Solutions give you great precision for 6-axis industrial robots. You need parts that fit just right for the best performance. CNC machining is very accurate, which helps make parts that follow strict rules.

Key Points on Precision:

Precision in CNC machining is key for making parts that fit exactly.

Tolerances are limits for how much parts can vary in size, ensuring they fit and work well.

Tools like calipers, micrometers, and CMMs check that parts meet the right tolerances.

Making the same parts over and over is important for mass production. This helps your robot run smoothly and reliably.

Durability is another big plus of custom machined solutions. You want your robot to last and handle wear over time. Surface treatments like anodizing or coating can make materials stronger, improving how long they last.

Benefit Description Precision Improvement CNC machining gives you great precision and accuracy, which is key for devices needing strict rules. Consistency and Repeatability Making the same parts over and over is important for mass production of devices. Durability Enhancement Surface treatments like anodizing or coating make materials stronger, improving device performance and life.

By choosing custom machined parts, you make sure your robot can do tough jobs without losing quality.

Custom machined solutions also help your 6-axis industrial robot work better overall. When parts fit together well, the robot works more efficiently. This means faster cycle times and better productivity.

You can expect better performance through:

Custom designs that fit specific needs.

Better energy use because of less friction and wear.

More flexibility for different tasks, letting your robot do many jobs well.

Custom joints and connectors help 6-axis robots move smoothly. These parts let robot arms move freely while staying stable. When making these parts, think about reliability, movement, and durability.

Specification Type Description Reliability Connectors must work well in tough conditions like heat or dust. Motion Dynamics Joints should handle fast, multi-directional moves without breaking. Environmental Resilience Connectors need to resist damage from moisture, dust, and dirt. Power Delivery Requirements Connectors must manage power flow and energy transfer efficiently.

Case Study:

A study on timber joints shows why custom joints matter. Using a 6-axis robotic arm (ABB 6400R/2.5-200), researchers tested joints for strength and easy assembly. They found the best designs and solved problems like assembly force. This improved the robot’s performance and made assembly easier.

Custom joints and connectors make robots more flexible and reliable in tough jobs.

Specialized mounting plates hold robot parts securely in place. These plates are made to solve problems like fitting different part sizes or shapes.

For example, a rotary gripper shows how special designs work. It rotates and grips parts from many angles, making alignment less important. This adds flexibility and saves time.

In another case, a robot system for timber used special plates for pneumatic grippers. These plates held timber pieces of different sizes and adjusted for errors. A force-torque sensor gave feedback for better assembly.

Specialized mounting plates help robots do many tasks with better accuracy and speed.

Tailored gear systems improve how 6-axis robots move and work. These gears transfer power from motors to moving parts, ensuring smooth motion. Standard gears often don’t meet complex robot needs.

Custom Machined Solutions let you design gears for your robot’s needs. You can make gears with special teeth to lower friction and save energy. Strong materials can also make gears last longer and reduce wear.

Tailored gear systems boost robot speed, accuracy, and performance. They also cut maintenance costs by making parts last longer.

Before fixing assembly issues, find the exact problems in your 6-axis robot. This step helps solve the main causes of errors or inefficiencies. Different methods can help with this process.

Diagnostic Method What It Does Quality-integrated diagnostic method Uses advanced tools and quality checks to fix assembly problems. Physical-based modeling approaches Finds errors by studying how problems spread during assembly. Deep learning and data-driven methods Uses sensors and computers to check for hidden assembly mistakes.

These methods help spot misaligned parts, weak materials, or design mistakes. For example, deep learning can study sensor data to find small errors that are hard to see. Fixing these problems early saves time and money during assembly.

Working with machining experts ensures your custom parts are top quality. These experts have special tools and skills to make parts that fit your robot perfectly.

Benefit/Outcome What It Means Risk Mitigation Finding problems early avoids delays and keeps things safe. Specification Alignment Makes sure the parts meet your robot's needs and work well. Project Management Keeps the project on time, within budget, and high quality.

Experts also help pick the best materials and methods for making parts. Their advice ensures your robot’s parts are strong, accurate, and work well. This teamwork lowers risks and keeps your project running smoothly.

Testing and improving are key steps for better custom parts. This means making prototypes, testing them in real situations, and fixing any problems. The Robot Scientists 'Adam' and 'Eve' show how testing works. They create ideas, test them, and improve their systems.

In robotics, testing helps make designs better and improves performance. For example, testing a custom gear might show where friction can be reduced. Fixing this makes the robot more efficient and parts last longer. Testing and improving ensure the final product meets all quality and performance goals.

Custom Machined Solutions bring great accuracy, strength, and efficiency to 6-axis robots. These custom parts help robots fit together perfectly, lowering mistakes and improving work speed. Using these solutions can lead to clear improvements in important areas:

KPI What It Measures Cost Savings Tracks how much money is saved by using automation. Return on Investment (ROI) Checks how much profit is gained compared to automation costs. Process Cycle Time Reduction Measures how much faster tasks are completed with automation. Error Rate Reduction Looks at how many fewer mistakes happen after automation. Employee Productivity Shows how automation helps workers get more done.

These advantages not only make your robot work better but also help your projec

Custom machined solutions make special parts for your robot. These parts are made to fit perfectly. They help with problems like parts not fitting, weak materials, and limits of regular parts.

Custom parts fit well, cutting down on friction and wear. This saves energy and helps the robot last longer. Special designs also make the robot more flexible, so it can do different jobs faster and better.

Yes, they are. At first, they might cost more. But they lower repair costs and stop delays. Over time, they save money and give you more value back.

First, find out what problems your robot has. Work with experts to make and build the parts you need. Test these parts to make sure they work well before using them fully.

Yes, they can! Custom parts can fit into your current robot setup. This lets you upgrade parts without changing the whole robot, saving time and money.

Latest News

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.