Apr.

08, 2025

Contents

The Future of Custom Automotive Parts Manufacturing

Key Technological Advancements in Custom Automotive Parts

Trends Shaping the Custom Automotive Parts Industry

Challenges and Solutions in Custom Automotive Parts Manufacturing

Future Outlook for Custom Automotive Parts

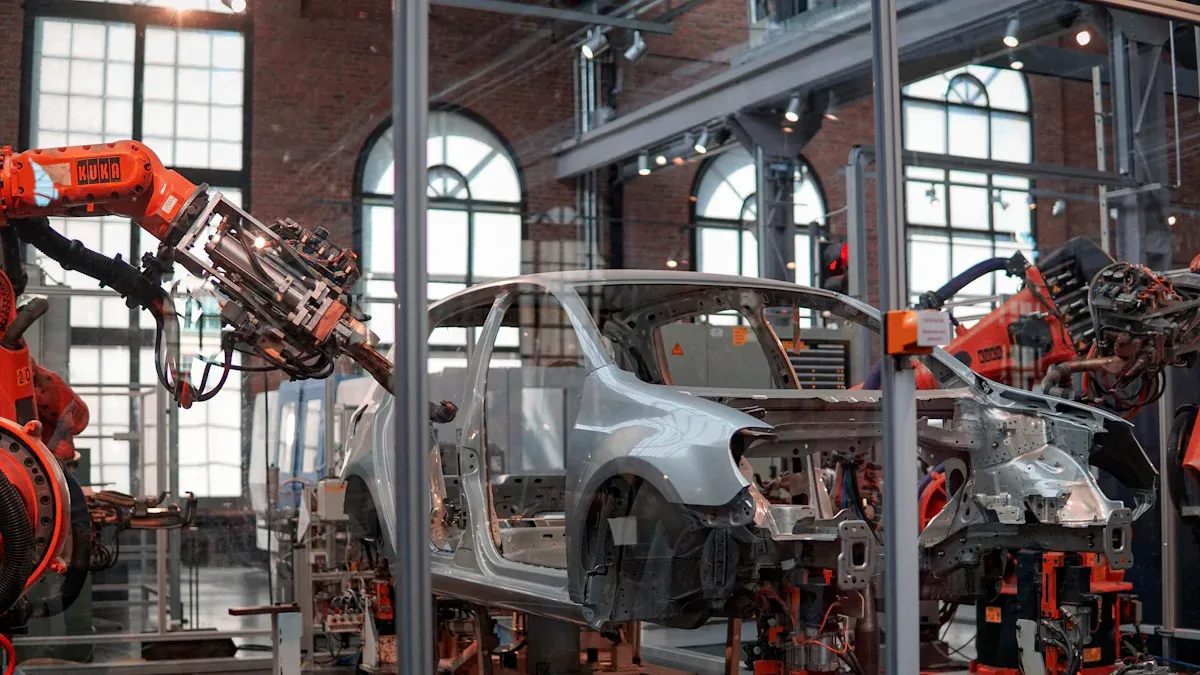

Custom automotive parts are changing how vehicles are made. These parts let you adjust cars for better looks, speed, or use. New ideas make building faster, smarter, and easier. Technology helps create special designs to fit what people want. With tools like 3D printing and AI, customizing cars with custom automotive parts will soon be common for everyone.

3D printing is changing how custom car parts are made. It helps create parts that are strong but not heavy. This is great for making tricky designs and parts that boost performance. For instance, companies now use metal 3D printing to work faster in testing and production. Big car brands are teaming up to improve 3D printing. These partnerships aim to make the process quicker and cheaper.

The numbers show how big this change is. By 2029, car product output may grow 5.8%, reaching $5.5 trillion. This shows more people want new ways to make car parts, like 3D printing.

AI is changing how custom car parts are designed and built. Tools like generative design help engineers make many ideas based on goals. Tesla uses this to create better car parts. AI also makes digital twins, which test car designs virtually. Ford uses this to fix designs before building, saving time and money.

AI is also helpful in smart factories. BMW uses AI robots to do tasks with care and less waste. These robots repeat jobs perfectly, reducing mistakes. From 2025 to 2030, the AI car market may grow 23.4% yearly, showing its growing role in the industry.

The Internet of Things (IoT) is making factories smarter and faster. IoT links machines so they can talk and work alone. This cuts down on human work and speeds up production. For example, IoT collects data to know when machines need fixing. This stops breakdowns and keeps things running smoothly.

IoT also boosts safety and saves resources. Machines work together better, making more while wasting less. A study shows IoT saves time, reduces effort, and improves efficiency. As IoT grows, it will shape how custom car parts are made in the future.

New materials are changing custom car parts in big ways. Materials like carbon fiber, strong steel, and special plastics make cars lighter and tougher. These materials help make parts that work better and weigh less. This is very helpful for electric cars, as lighter parts make batteries last longer and cars go farther.

Car companies are leading the way in using these new materials. They need lighter and stronger parts more than ever. Electric cars and eco-friendly goals are pushing this change. Companies spend a lot on research to make better materials. For example, new metals and plant-based materials are replacing old ones. These changes make cars better and help the planet.

Why do lighter materials matter? A lighter car uses less energy, whether gas or electric. This means it pollutes less and saves fuel. Stronger materials also make cars safer in crashes by absorbing more force. These reasons make new materials important for future car parts.

Eco-friendly ideas are also bringing recycled and renewable materials into use. Some companies now use recycled carbon fiber or plant-based plastics. These materials are just as strong but harm the planet less. As technology grows, even cooler materials will change how cars are made.

Electric vehicles (EVs) are changing the car industry fast. More people are buying EVs, so the need for special parts is growing quickly. By 2030, the market for EV parts may grow from $150.92 billion in 2025 to $395.02 billion. This is a yearly growth of 21.22%. Governments are spending money on electric cars, and people care more about the environment. By 2025, over 5 million electric cars may sell each year, making up 15% of all car sales.

Lightweight and efficient parts are key for EVs. These parts help batteries last longer and cars drive farther. Because of this, companies are working hard to make better parts for EVs. This shows how important custom car parts are for the future of electric cars.

Making cars in eco-friendly ways is now very important. Companies are using green methods to lower harm to the planet. For example, Europe has rules to encourage recycling and using reused materials. Big brands like Mercedes-Benz and Renault Group now use recycled and renewable materials in their factories.

Car makers are also saving energy and water to cut waste. These changes help the planet and save money too. By focusing on eco-friendly ideas, the car industry is moving toward a greener future.

Did you know? Recycled carbon fiber and plant-based plastics are now used to make strong, light car parts. These materials work as well as old ones but are better for the planet.

Smart factories are changing how custom car parts are made. These factories use robots, automation, and data to make things better. For example, Porsche uses automated vehicles and digital plans to work faster. Siemens uses smart tools to predict and improve production steps.

Robots are a big help too. By 2020, over 3 million robots were working in factories, growing by 14% each year. Robots do the same tasks perfectly, making fewer mistakes and speeding up work. Smart factories can also change quickly to meet new needs.

With more automation, factories will make parts faster and cheaper. The quality of custom car parts will also improve. This trend is setting new goals for how car parts are made.

More people now want cars that match their style. This growing interest is changing how cars are made. Customization is becoming a big focus for car makers.

Personalization lets you pick parts that fit your needs. Some people choose custom wheels or spoilers to make their cars look cooler. Others prefer special interiors or tech features for comfort. This shows how much people care about making their cars unique.

Studies show this demand is increasing. The table below shares details about consumer trends:

Source Type of Evidence Description Parts/Service Consumer Segmentation (CCAMS+PRIZM) Forecasting Looks at revenue growth and trends in car parts from 2017 to 2030. Consumer Demographics Demographic Insights Shares data about car parts buyers, helping with product customization. DIY Decision Process Research Consumer Behavior Studies DIY buyers, showing their interest in custom parts.

Different people like different things. Younger drivers often want trendy designs. Older drivers may prefer comfort and durability. DIY fans enjoy working on their cars themselves.

Custom car parts let you make your car feel personal. As technology improves, more options will be available. This will make it easier for everyone to customize their cars.

Tip: Want to customize your car? Start by picking parts that match your lifestyle. This helps you get the best value for your money.

Material problems can slow down making custom car parts. Some materials may not be strong or flexible enough for new designs. But new ideas are solving these problems.

Better manufacturing methods make materials like polymers stronger and more useful.

Scientists are creating new materials to replace old ones. For example, stronger and lighter polymers are being made for cars.

Future studies may focus on eco-friendly materials and smarter ways to make parts.

These improvements help provide better materials for modern car-making needs.

Making custom car parts fast while keeping them good is hard. You can solve this by using smart steps:

Make clear rules for part quality.

Teach workers about production goals.

Use tools to check production as it happens.

Work with suppliers to get good materials.

Use customer feedback to improve work.

These steps help keep quality high and meet deadlines. Watching production in real-time helps fix mistakes quickly and waste less.

Car-making has many strict rules to follow. You need to meet rules for safety, pollution, and design. Staying updated on these rules is very important.

Rules are different in each country, so learn them well.

Collect data to show you are following the rules.

Watch for changes in rules about self-driving cars and the environment.

By staying informed, you can follow the rules and avoid problems in making car parts.

Keeping costs low is key to making custom car parts for everyone. You might ask how companies make custom parts without high prices. The answer is using smart ideas and new methods.

One way is by improving how supplies are managed. Companies can save money by cutting waste and extra costs. For example, a big car company used better tech and supply plans to lower costs. This helped them save money while still focusing on custom parts.

Using robots also saves money. Robots do the same jobs over and over perfectly. This lowers worker costs and avoids mistakes. Robots also make parts faster, so you get them sooner.

Another idea is making parts in bulk that can be changed later. Instead of making each part from scratch, companies make basic parts that can be customized. This keeps costs down but still lets you personalize your car.

Better materials can also save money over time. Strong and light materials like carbon fiber cost more at first. But they use less energy to make and help cars run better. This helps both companies and buyers save in the long run.

By using these ideas, companies keep custom car parts affordable. This means you can make your car special without spending too much.

Hybrid manufacturing mixes old methods with new tech like 3D printing. This helps make car parts that are strong and light. For example, CNC machines work with 3D printers to create better parts. This mix reduces waste and improves quality.

Car makers are using hybrid methods to meet new demands. A report shows new materials and processes are helping the market grow. These methods let companies quickly adjust to what customers want, like parts for electric cars.

Hybrid manufacturing also helps the planet. Using eco-friendly materials and processes lowers harm to the environment. This makes hybrid techniques important for the future of car parts.

On-demand production changes how car parts are made. Instead of making many parts at once, companies make them only when needed. This saves money and reduces waste. One company cut production time by 30% using this method. It also made customers happier by offering custom options.

With on-demand production, you get parts faster and made just for you. This is great for electric cars, which need special parts like batteries. As more people buy electric cars, this method will grow even more.

On-demand production also helps invent new ideas. Making small batches lets companies test new designs and materials. This means you get the latest and best parts for your car.

Digital tools are changing how car parts are made. Smart factories and digital twins help test ideas before spending money. Siemens used a digital twin to save costs and work better.

Digital tools also make factories more productive. Studies show they can boost work speed by 30%. Some factories make twice as many parts while cutting costs by 70%. This means you get better parts for less money.

Digital systems also check for mistakes during production. They catch problems early, so parts are made right the first time. This leads to faster delivery and higher quality. As digital tools improve, they will shape how car parts are made in the future.

Big changes are coming to car parts manufacturing in the next ten years. Technology, money matters, and what people want will drive these changes. These things will decide how car parts are made, designed, and delivered.

The industry is expected to grow steadily. Experts say money issues, taxes, and new tech will affect this growth. For example, a 25% tax on key materials could raise costs. This might make it harder to get supplies. Higher interest rates could also make people spend less on cars and parts. Here's a simple table of these predictions:

Aspect Insight Market Growth Car parts manufacturing is expected to grow in the next decade. Economic Factors Money issues, taxes, and tech will shape the industry's future. Tariffs Impact A 25% tax on materials may raise costs and hurt supply chains. Interest Rates Higher interest rates could lower people's confidence to buy cars and parts.

More companies will use eco-friendly methods. They will choose greener materials and save energy to follow stricter rules. This matches the rise of electric cars, which need lighter and better parts.

Digital tools will keep changing how factories work. Smart factories and digital twins will make production faster and more accurate. These tools will help companies meet new demands and give you better custom car parts.

The future of car parts looks bright. With a focus on new ideas, green practices, and digital tools, the industry is ready to face challenges and make better products for you.

The custom car parts industry is changing fast. New technology and what people want are driving this change. Tools like 3D printing, AI, and mixed manufacturing are making parts in new ways. Trends like more electric cars and eco-friendly ideas show the focus on saving energy and helping the planet.

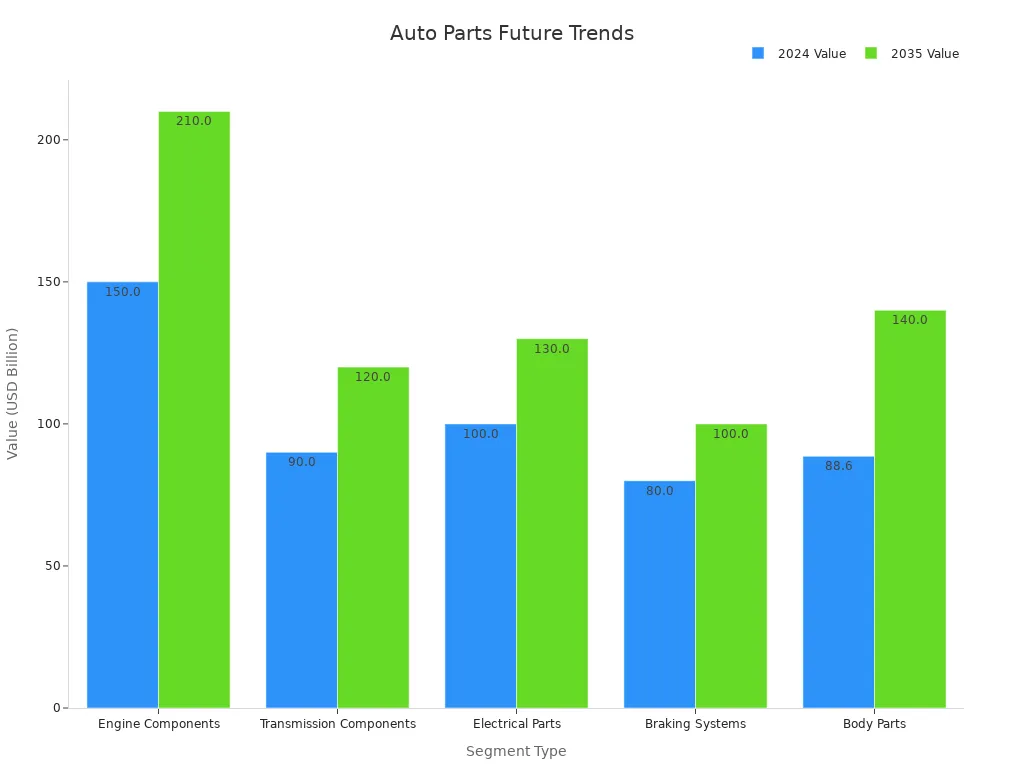

There are still problems like weak materials and strict rules. But smarter ways to make parts and green materials are solving these issues. For example, engine parts sales may grow from $150 billion in 2024 to $210 billion by 2035. This shows people want better and stronger parts.

To succeed, companies must stay creative and flexible. As technology improves, custom car parts will keep changing the car

Custom car parts are special pieces made to fit your car. They improve how your car looks, works, or performs. These parts let you make your car match your style or needs.

3D printing makes strong, light parts with tricky designs. It works faster and wastes less. You can get custom parts quickly and for less money than older methods.

Yes, custom parts are very important for electric cars. They make batteries last longer, lower weight, and improve performance. These parts are made to work well with electric cars.

Yes! Many companies now use recycled materials and save energy. These steps help the planet while keeping parts high quality. Picking eco-friendly parts supports green ideas in car-making.

Custom parts are getting cheaper thanks to new technology. Companies use smart designs so you can customize without spending too much. There are options for every budget.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.