Apr.

08, 2025

Contents

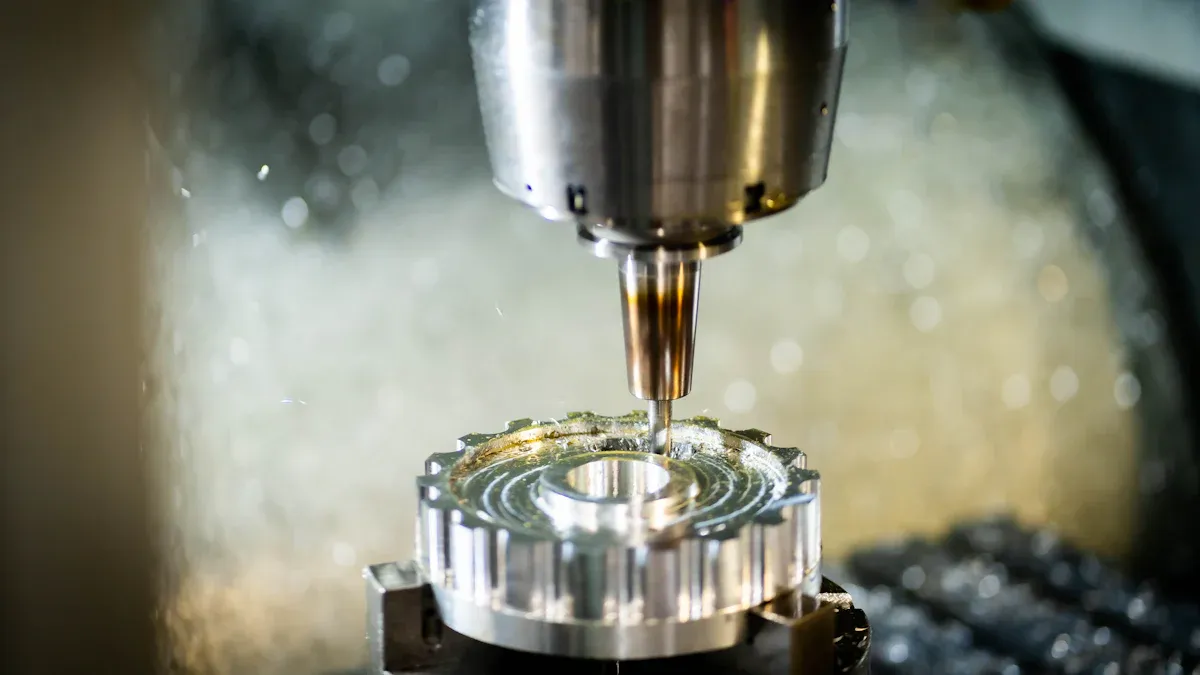

How We Helped a Client Reduce Production Costs with CNC Machining

CNC Machining Strategies to Reduce Production Costs

Results of Using Cost-Saving Strategies

Lessons for Manufacturers on Cutting Costs

Reducing production costs is very important for businesses today. In the past five years, costs have gone up by 7.2% each year, making it harder for companies to save money. One of our clients faced challenges with wasted materials, slow processes, and complicated designs, which hindered their ability to reduce production costs and maintain profitability while keeping up with demand. By utilizing CNC machining, we assisted them in simplifying designs, optimizing material usage, and accelerating production.

High production costs can hurt profits a lot. For our client, these costs came from wasted materials and slow processes. Studies show that changes in raw material prices cause 43% of cost changes. This shows how important it is to pick the right materials to save money. Also, using regression-based improvements can lower per-unit costs by 7.3%, making it easier to cut expenses.

Data Point Details 2 Models explain 84% of cost factors in large-scale production. 5 Real-time analysis improves cost predictions by 42%. 9 Better inventory management lowers storage costs by 26%.

These facts show why using data is key to cutting costs and boosting profits.

Problems in manufacturing can slow work and raise costs. For our client, bottlenecks delayed production and caused unfinished work to pile up. This used up resources and raised extra costs. Common problems include:

Bottlenecks that slow down production.

Piles of unfinished work that waste resources.

Rushed fixes for delays that lower quality.

Running out of materials stops production.

Late deliveries from suppliers cause delays.

Broken machines lead to unexpected stops.

Fixing these problems is important to make work faster and cheaper.

Wasting materials and having hard-to-make designs raise costs. Our client struggled with too much scrap material and designs that took extra time and effort. Choices in design and production affect costs a lot. For example, custom projects often need special materials, which cost more.

Factor Effect on Costs Design and Production Choices Big impact on costs, showing the need for better planning. Custom Projects Special materials or setups for unique jobs raise expenses. Manufacturing Quality Better quality means less rework and safer products, saving money on installation.

Simpler designs and smarter material use can cut costs while keeping good quality.

Simpler designs can lower production costs a lot. Fewer parts in a product mean less material and faster assembly. For example, Senaptec Strobe Eyewear cut parts from 22 to 9. This made tools easier to use and saved money. Another project reduced assembly time from 8 hours to 1 hour. They did this by cutting parts from 25 to 5. These changes saved money and made products work better.

Better designs also make manufacturing faster. Turning complex features into simple ones saves time and materials. This way, products stay high-quality but cost less to make.

Choosing the right materials and using them the same way helps save money. Buying the same materials in bulk costs less. It also makes storing parts easier by needing fewer types. Studies show standardizing materials can cut costs by 50%.

Picking strong and affordable materials is also smart. Good materials make better products and last longer. This saves money and keeps customers happy with reliable items.

Improving how things are made can save money too. CNC machining makes production quicker and more accurate. This reduces mistakes and waste. One company made 30% more products and cut costs by 20%. They did this by using materials better and CNC technology.

Fixing problems from start to finish helps save time and money. Lean manufacturing finds ways to improve and cut waste. CNC machining also uses less energy and creates less waste. This makes it a great choice for modern factories.

Mass production works well with CNC machining. It automates repeated tasks, making products faster and keeping quality steady. CNC machining ensures every part matches exact designs. This is very important for industries like healthcare and aerospace. Accurate parts mean fewer mistakes and less expensive fixes.

Tip: Automating tasks with CNC machining saves time and avoids errors. This boosts efficiency and lowers costs.

Mass production also saves money. Instead of buying costly machines or hiring skilled workers, you can use CNC machining services. These services offer advanced tools without needing big investments. Making items in bulk lets you use the same materials, which cuts costs. Studies show using standard materials can lower expenses by 50%.

Experts in CNC machining can improve how you make products. They help with designs and production steps to save money. For example, an aerospace company cut costs by 25% by simplifying a tricky part. Another car supplier avoided losing $2 million by using CNC machining nonstop during delivery problems.

Example Problem Fix Savings Aerospace Company Expensive part design Easier design with DFM 25% cost savings Car Supplier Delivery issues 24/7 CNC machining $2M saved Medical Tool Maker Needed strong tools Precise machining with tough alloy 20% more market share

Experts also use data to find ways to improve. Tools like MachineMetrics show how to make production better. This data helps you plan smarter and improve results. By teaming up with experts, you can save money, work faster, and make better products.

Using CNC machining can save money and speed up work. Simpler designs use fewer materials and take less time to assemble. This reduces waste and keeps quality steady.

Checking expensive machines for quick payback saves money over time.

Using machines for more shifts lowers costs per hour.

Tip: Improving production with CNC machining avoids delays and increases efficiency. This helps you finish on time without losing quality.

CNC machining helps use materials wisely, cutting waste at every step. Smarter processes mean less scrap and better use of resources. Lean Manufacturing finds wasteful steps and removes them.

Reduce: Make processes better to create less waste.

Reuse: Use materials longer to avoid throwing them away.

Recycle: Turn waste into new items to help the environment.

Performance Measure Improvement Range Faster production 25–50% Less material waste 25–50% Better production efficiency 15–40%

Better processes also mean fewer mistakes and smarter machine settings. This ensures resources are used well.

CNC machining improves product quality and makes work simpler. Data tools help find problems and fix supply chain issues. Predictive maintenance keeps machines running smoothly.

Gather data from all production steps.

Use charts to check for steady operations.

Study data to find and fix problems.

Checking quality often helps catch issues early. This stops defects and keeps products consistent. It also cuts waste and ensures high standards.

Note: With CNC machining, you can lower costs and still make great products for your customers.

Making smart design choices helps lower production costs. Simple designs use less material and make manufacturing easier. For example, tracking material and energy use in turbine blade production improves efficiency. This system helps save resources and money.

Picking the right materials is just as important. Strong and affordable materials cut costs and make products last longer. Studies show that managing costs wisely, like improving supply chains and using eco-friendly methods, saves money while keeping quality high. By focusing on better designs and materials, you can save money without losing quality.

Teaming up with skilled CNC machining experts has many benefits. These professionals ensure precise and reliable manufacturing. For example, CNC machining is crucial in healthcare for making accurate surgical tools. This precision prevents mistakes and avoids expensive fixes.

Experts also use advanced tools and predictive maintenance to help. Predictive maintenance reduces unexpected machine stops by 30% and cuts repair time by 75%. This keeps machines running longer and improves production. By working with experts, you can focus on your business while they handle the technical details.

Efficient manufacturing brings lasting rewards for businesses. It boosts productivity, reduces waste, and supports sustainability. For example, companies using foreign technology or getting government help often work more efficiently. Training employees also increases productivity in different industries.

Evidence Type Key Findings Green Practices Companies with eco-friendly goals are the most efficient. Foreign Technology Use Improves material quality and management skills. Employee Training Boosts efficiency in all industries. Government Support Supported companies perform better than those without help. Company Size Bigger companies tend to be more efficient.

By adopting efficient methods, you can cut costs, improve product quality, and stay ahead in the market.

CNC machining helped the client save money and work faster. By making designs simpler, using materials better, and improving processes, they saved a lot and made better products. Planning carefully was key to matching cost-saving with business goals.

Cutting production costs increases profits and keeps businesses strong.

Smart cost planning links money choices to work decisions for savings.

Source of Evidence Important Findings Using smart cost planning in factories Shows why managing costs and matching them to business plans matters, especially in tough times.

Check out CNC machining to get these benefits for your business.

CNC machining uses computers to control tools for making parts. It saves money by using less material, working faster, and keeping quality steady. You avoid mistakes and extra work, which lowers costs.

Yes, CNC machining is great for detailed designs. It makes precise parts without losing quality. This reduces the need for fixing mistakes, saving time and materials.

Picking the right material saves money by cutting waste and lasting longer. Using the same materials makes storage easier and buying in bulk cheaper.

Yes! CNC machining works well for small and big jobs. For small batches, it skips the need for costly tools, making it a smart choice.

Experts improve designs, pick affordable materials, and make processes better. They help you get great results while saving time and money. Working with them avoids expensive errors.

Tip: Talk to CNC experts to save money and work smarter.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.