Apr.

16, 2025

Contents

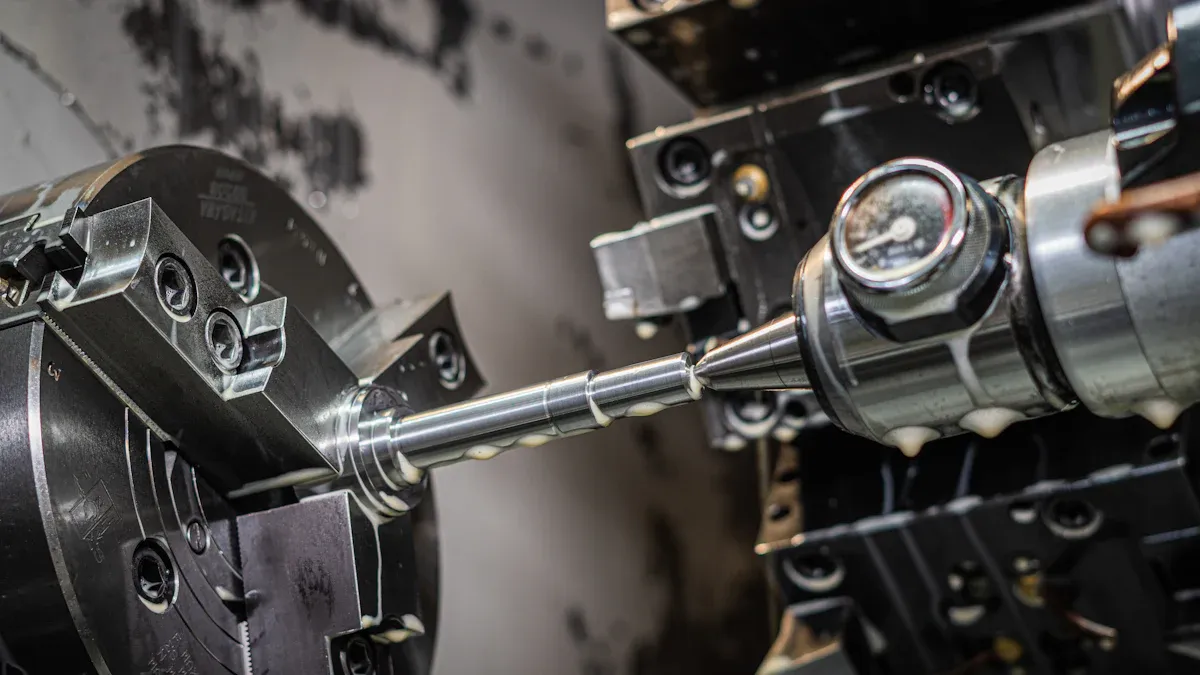

What is 5-Axis CNC Machining and When to Use It

How 5-Axis CNC Machining Works

Advantages of 5-Axis CNC Machining

Applications of 5-Axis CNC Machining

When to Use 5-Axis CNC Machining

5-Axis CNC Machining is a way to make parts. It moves tools or pieces along five directions at the same time. This helps create detailed and precise parts quickly.

This method is great for improving accuracy and lowering mistakes. For example:

Surface smoothness improves from 44.4 μm to 4.5 μm.

Mistakes drop by about 89.9%.

These benefits make 5-Axis CNC Machining perfect for making tricky parts that need to be very exact.

5-Axis CNC Machining is a modern way to make parts. It uses special tools to cut materials into exact shapes. Unlike older methods, it works on five directions at once. These include the X, Y, and Z axes, plus two rotating axes. This lets it create detailed shapes with great accuracy.

The process starts with a CAD file. This file is turned into a CAM program, which makes the G-code. The G-code tells the machine how to move and cut. This system reduces the need for manual work, making it faster and more reliable.

Key features of 5-Axis CNC Machining are:

It can make very detailed shapes with tight measurements.

Shorter tools improve surface quality by reducing vibrations.

It drills better, handling tricky angles with ease.

A single setup lowers alignment mistakes, keeping quality steady. This makes 5-Axis CNC Machining a great choice for industries needing precise work.

5-Axis CNC Machining is different from 3-Axis and 4-Axis machining. Each has its own strengths, but 5-Axis is the most accurate and efficient.

Feature 3-Axis Machining 4-Axis Machining 5-Axis Machining Precision Okay Better Best Complexity Simple Medium Complex Efficiency Many setups Fewer setups One setup Ideal for Easy parts Medium parts Hard parts Cost Cheaper Medium Expensive

3-Axis machining moves along three straight lines (X, Y, Z). It works for simple parts but needs many setups for harder shapes. This can cause mistakes and alignment problems.

4-Axis machining adds one rotating axis, making it more accurate. It also needs fewer setups. But it struggles with very detailed designs or tight measurements.

5-Axis CNC Machining beats both by working in one setup from any angle. It saves time and keeps quality high. It’s perfect for industries like aerospace and medical, where precision is key.

Tip: Choose 5-Axis CNC Machining for detailed designs or high accuracy. It cuts errors, saves time, and works efficiently.

A 5-Axis CNC machine moves tools or parts in five ways. It uses three straight axes (X, Y, Z) and two rotating axes (A, C).

The X, Y, Z axes move left-right, forward-backward, and up-down.

The A-axis tilts the table for angled cuts.

The C-axis spins the table to shape complex designs.

These movements work together for precise and detailed machining. The machine follows G-code commands to control tool and table movements. This ensures high accuracy and smooth surfaces.

Tip: Knowing the five axes helps you see how 5-Axis CNC Machining makes detailed parts faster.

There are three main kinds of 5-Axis CNC machines, each for specific jobs.

Type Description Best Use Head/Head Two rotating axes in the spindle head, avoiding tool clashes. Great for fixed workpieces. Table/Head Rotating axes in both head and table, with limited head range. Works for many projects. Table/Table Both rotating axes on the table, slower with limited rotation. Best for undercut machining only.

Each type has its own strengths. For example, Head/Head machines are great for fixed parts. Table/Head machines handle many tasks. Table/Table machines are slower but good for undercuts.

5-Axis CNC Machining works in two ways: simultaneous or 3+2 machining.

Simultaneous 5-Axis Machining moves all five axes at once. It creates very complex shapes with smooth finishes. But it takes longer to set up and may cause tool bending.

3+2 Machining locks two rotating axes while the straight axes move. This makes it easier and faster to set up. It’s good for parts that don’t need constant movement.

Feature Simultaneous 5-Axis Machining 3+2 Machining Tool Motion Complexity High Lower (simpler) Surface Finish Quality Higher Good, but less consistent Setup Time Longer Shorter Application Flexibility More versatile Limited to fewer tasks

Use simultaneous machining for detailed designs. Choose 3+2 machining for simpler parts with fewer angles.

5-Axis CNC Machining gives amazing precision and accuracy. Tools move in five ways, making every cut exact. A study shows advanced tools improve results with constant checks. Using a 1D-CNN model, it detects operations with 95.7% accuracy. Feed rates are also tracked with 91.4% accuracy. These tools ensure parts meet strict standards. This makes it perfect for industries like aerospace and medical.

Note: Precision means more than meeting specs; it ensures steady quality.

5-Axis CNC Machining saves time by cutting down setups. Older methods need moving the part often, causing errors. With 5-Axis, you finish complex parts in one setup. Research shows better tool paths improve speed and performance. Another study proves it reduces setup time for aerofoil parts. This method boosts productivity and delivers quality parts faster.

Making tricky designs is easy with 5-Axis CNC Machining. It mills complex shapes in one setup, no manual fixes needed. Industries like defense and medical use it for precise parts. It also creates parts for heavy machines like gearboxes. By solving these challenges, 5-Axis machining ensures parts fit perfectly.

Tip: Use 5-Axis CNC Machining for tight angles or detailed designs. It ensures perfect results every time.

If you need parts with a smooth surface, 5-Axis CNC Machining is the best choice. This advanced method reduces tool shaking and makes cleaner cuts. It also avoids alignment mistakes by needing fewer setups.

Shorter cutting tools are very important in this process. These tools stay close to the material, which stops bending and shaking. This gives a shiny finish without extra sanding or polishing. It saves time and keeps all parts looking the same.

Did you know? A smooth surface doesn’t just look nice; it works better too. For example, in airplanes, smoother surfaces lower air resistance and save fuel.

Here’s how 5-Axis CNC Machining makes surfaces smoother:

Constant tool contact: The tool stays in touch with the material, avoiding sudden stops.

Accurate angles: It easily handles tricky shapes, making every edge smooth.

Fewer manual changes: With fewer setups, there’s less chance of mistakes ruining the finish.

Think about making a turbine blade or a medical device. These need both accuracy and a perfect surface. 5-Axis CNC Machining meets these high demands every time.

Tip: For projects needing a great surface finish, pick 5-Axis CNC Machining. It cuts down extra work and gives ready-to-use parts.

Using this technology ensures your parts are both useful and good-looking. It’s a smart choice for industries where quality is very important.

The aerospace industry uses 5-Axis CNC Machining for detailed parts. It makes turbine blades and engine parts with high accuracy. These parts must meet strict safety and quality rules. Horizontal 5-axis machines are becoming more popular. They handle heavy-duty tasks and large, complex pieces well. Their design helps remove chips and cool parts faster. This keeps aerospace components strong and reliable. With 5-Axis CNC Machining, parts are lightweight but tough, meeting the industry's needs.

In medicine, precise parts are very important. 5-Axis CNC Machining helps make implants and surgical tools with exact measurements. It creates tricky shapes needed for medical devices. As demand grows, more manufacturers use this technology. It ensures medical parts are safe and work well. 5-Axis CNC Machining delivers the precision required for top-quality medical devices.

The automotive industry gains a lot from 5-Axis CNC Machining. It makes complex shapes that older methods can't handle. This improves car parts and boosts vehicle performance. Compared to older machining, 5-Axis CNC Machining has many benefits:

Efficiency: Works much faster

Accuracy: Produces highly precise parts

Production Speed: Makes parts quicker

Complexity of Geometries: Handles tricky shapes easily

Setup Requirements: Needs fewer setups

Using 5-Axis CNC Machining speeds up production and meets high demand. It’s better than older methods for making detailed designs and undercuts.

The energy sector uses advanced tools to meet growing needs. 5-Axis CNC Machining helps make strong and precise parts for energy systems. It’s great for creating items like wind turbine blades, solar panel frames, and power plant parts.

This technology ensures parts are accurate and reliable. Energy systems need parts that handle tough conditions, like heat or heavy loads. For example, wind turbine blades must be exact to work well. Even small mistakes can lower energy output.

Automation in 5-Axis CNC machines speeds up making parts. It reduces manual work, so more parts are made faster. These machines also work with many materials, like lightweight composites and strong metals. This makes energy solutions last longer and perform better.

Here’s why 5-Axis CNC Machining is useful for energy:

Better Precision: Needed for wind turbine blades and solar panel frames.

Faster Production: Automation saves time.

Reliable Parts: Quality stays steady, reducing defects.

Material Options: Handles different materials for stronger parts.

Cost Savings: Cuts labor and waste, saving money.

Using 5-Axis CNC Machining helps make energy parts efficient and affordable

Use 5-Axis CNC Machining for detailed designs or tight fits. It’s great for making tricky shapes that other methods can’t handle well. Industries like aerospace and medical use it to make turbine blades, implants, and tools with high accuracy.

Here’s why it works so well:

Unmatched Versatility: Handles tough shapes, opening up more project options.

Broader Market Reach: Works for many industries, growing your customer base.

Unprecedented Precision: Makes exact parts that stand out in quality.

Reduced Setup Time: Cuts from many angles in one go, saving time.

Enhanced Accuracy: Less movement means fewer mistakes and better results.

Increased Productivity: Faster setups lead to more parts made quickly.

Lower Production Costs: Saves money by being efficient and accurate.

Advantage Description Unmatched Versatility Handles hard shapes, giving more design options. Broader Market Reach Works for many industries, helping you reach more buyers. Unprecedented Precision Makes exact parts with tight fits, improving quality. Reduced Setup Time Cuts from all angles in one setup, saving time. Enhanced Accuracy Fewer movements mean fewer errors and better precision. Increased Productivity Faster setups and processes make more parts quickly. Lower Production Costs Efficiency lowers costs while keeping quality high.

If your project needs exact cuts, tricky designs, or faster work, 5-Axis CNC Machining is the best choice.

Before picking 5-Axis CNC Machining, think about these points to see if it fits your project:

Design Complexity: If your part needs cutting from many angles or has tricky shapes, this method is perfect. The extra rotating axes (A and B) let tools cut from almost any angle, keeping cuts smooth and accurate.

Precision Needs: Industries like aerospace and medical need very exact parts. 5-Axis CNC Machining is great for making parts with tight fits.

Speed of Production: Want to save time? This method skips extra setups and tool changes, making work faster.

Budget: These machines cost more than 3-Axis or 4-Axis ones. But for tough projects, their speed and accuracy are worth it.

Operator Skills: Running these machines takes special training. Make sure your team is ready or willing to learn.

By thinking about these factors, you can decide if 5-Axis CNC Machining is right for your needs.

Compared to other methods, 5-Axis CNC Machining stands out. It’s more precise, faster, and flexible, making it the top choice for tough projects.

Factor 3-Axis 5-Axis Cutting tool movement Moves on X, Y, Z axes Moves on X, Y, Z, A, and B axes Efficiency Good Excellent, very fast Tool changes Needs many setups Few setups, cuts from all angles Capabilities Simple shapes only Handles tricky shapes and deep cuts Accuracy Good Excellent Ease of operation Easy to learn Needs special training Cost $25,000 to $50,000 $80,000 to $500,000+ Maintenance/operating costs Low Higher Cost per part Lower Higher, but faster for hard parts Maintenance needs Low High, needs regular care Wear and tear Less More, due to extra moving parts Applications Simple car or plane parts Complex engine parts, medical tools

For easy parts, 3-Axis machining works fine. But for tricky designs or exact cuts, 5-Axis CNC Machining is better. It saves time by cutting from all angles in one setup and keeps quality steady.

Tip: Pick 5-Axis CNC Machining for jobs needing precision, speed, and tricky shapes.

5-Axis CNC Machining is precise, fast, and very flexible. It makes creating complex parts easier, saving time and keeping quality steady. This method is important in industries like aerospace, medical, and cars, where accuracy matters a lot.

If your work needs detailed designs or exact parts, try this advanced method. It boosts speed and ensures your parts are top quality.

You can use many materials like aluminum, titanium, steel, plastics, and composites. This makes it useful for industries needing different material choices.

Tip: Pick materials based on your project’s strength and durability needs.

Yes, it saves time and reduces mistakes, lowering total costs. While it costs more upfront, its speed and accuracy make it great for complex tasks.

Note: For detailed or large projects, the time and quality savings are worth it.

It uses shorter tools and accurate movements to stop vibrations. This creates smooth surfaces without needing extra polishing.

Did you know? Smooth surfaces help in aerospace by cutting air drag and boosting efficiency.

These machines need special training to use. Beginners can learn with practice, but experts get the best results.

Tip: Take training courses to use the machine safely and effectively.

Industries like aerospace, medical, automotive, and energy benefit a lot. They need precise parts, tricky shapes, and fast production.

Industry Example Uses Aerospace Engine parts, turbine blades Medical Surgical tools, implants Automotive Molds, engine components Energy Wind turbine blades

Reminder: Use 5-Axis CNC Machining for jobs needing accuracy and complex designs.

Latest News

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.