Jan.

07, 2025

Contents

Common Equipment-Related Micro Machining Failures

Critical Technical Parameters That Lead to Failure

Environmental Factors Causing Micro Machining Problems

Advanced Solutions for Technical Challenges

Preventive Maintenance Strategies

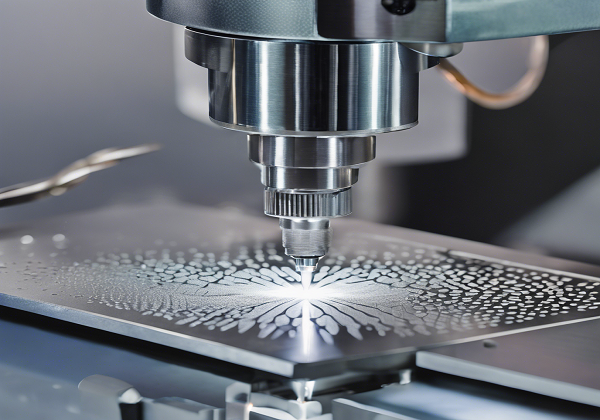

Precision manufacturing tolerances as small as 1/1000th of a millimeter can mean the difference between success and failure in modern manufacturing. Micro machining, while revolutionary for creating microscale components, faces numerous challenges that can lead to costly production errors and delays.

Indeed, many manufacturers struggle with equipment issues, technical parameters, and environmental factors that affect micro machining accuracy. Understanding these common failure points and their solutions helps prevent production delays and ensures consistent quality. This comprehensive guide examines the critical factors behind micro machining failures and provides expert solutions to overcome these challenges.

Equipment-related failures present significant challenges in micro machining operations. Specifically, these issues can dramatically impact production quality and efficiency when working with components smaller than 3mm in diameter .

Tool wear and breakage represent fundamental challenges in micro machining operations. The most common wear patterns include:

Flank wear along cutting edges

Adhesive material buildup

Micro-chipping

Coating peeling

Substrate tearing

Edge fracture

Furthermore, unpredictable tool life and premature tool failure frequently occur in micro-scale operations . Consequently, tools require ultra-fine grain carbide construction with submicron grain size to ensure high abrasion resistance and maintain toughness .

Machine calibration directly affects dimensional accuracy in micro machining. Particularly, calibration errors often stem from three primary sources:

Machine calibration inconsistencies

Material variations

Environmental factors

To maintain precision, micro-milling applications require 0.1 micron glass scales rather than the standard 0.5 micron version . Additionally, proper machine isolation becomes crucial, as even external vibrations from passing vehicles can affect surface quality .

Temperature management represents a critical aspect of micro machining success. Thermal damage frequently occurs due to:

High-speed operations

Insufficient cooling systems

Excessive friction between tool and workpiece

Moreover, polymer concrete machine frames provide up to 10 times higher vibration absorption compared to cast iron, helping maintain thermal stability . For optimal results, the machining environment must maintain controlled temperature conditions to prevent thermal-induced errors .

Technical parameters form the backbone of successful micro machining operations. Understanding these critical factors helps prevent costly failures and ensures optimal production outcomes.

Accurate speed and feed calculations are essential for micro machining success. A chip load that is too large can cause poor chip evacuation and eventual breakage, although a load that is too small leads to rubbing, chatter, and tool deflection . Finding the right balance is crucial for tool longevity and cut efficiency.

For optimal results, machinists must consider:

Surface finish requirements

Tool diameter specifications

Material characteristics

Machine capabilities

The depth of cut significantly influences machining outcomes. Generally, the minimum depth of cut starts at 0.1 mm for finishing operations, although maximum depths can reach up to 10 mm depending on the process .

Incorrect depth settings can trigger several issues:

Accelerated tool wear

Compromised material integrity

Surface finish defects

Increased operational costs

Studies show that an average speed of 60 m/min combined with a depth of cut of 0.3 mm and low feed of 0.1 mm/min typically yields optimal results 1. Nonetheless, these parameters must be adjusted based on specific application requirements.

Material-tool compatibility stands as a fundamental factor in micro machining precision. Different materials respond uniquely to machining processes, accordingly affecting the final product's quality . Subsequently, tool selection must account for specific material properties to prevent premature wear and ensure dimensional accuracy.

High-quality, wear-resistant materials become essential when working with challenging substances. The formation of Built-up Edge (BUE) occurs more frequently with annealed metals than cold-worked ones . Therefore, operators must adjust cutting parameters based on material characteristics to prevent surface finish deterioration.

Thermal considerations play a vital role in material-tool interactions. Deeper cuts increase friction and heat generation, which can alter material properties and affect tool life . Similarly, excessive cutting forces can lead to tool deflection or breakage, especially when using slender or extended tools.

Environmental control stands as a crucial factor in achieving precision in micro machining operations. First of all, understanding how environmental variables affect machining outcomes helps manufacturers maintain consistent quality standards.

Temperature variations as small as 0.1°C can cause significant measurement errors in micro machining operations . In fact, the human body alone generates approximately 120 watts of heat output—equivalent to two mid-sized incandescent bulbs—affecting nearby precision measurements .

Key temperature-related challenges include:

Thermal expansion of materials

Guideway element distortion

Tape scale sensitivity

Component deformation

Machine vibration presents complex challenges in ultra-high speed precision micro-milling 5. As a result, even minor vibrations can compromise machining accuracy and surface finish quality. The impact becomes more pronounced as measurement points move away from the tool tip, making sensor placement crucial for accurate readings .

Vibration sources often originate from:

Machine tool structure

Material properties

Processing parameters

Tool runout

Contamination during micro machining operations can certainly alter both mechanical and electrical properties of components . The rule of thumb indicates that particles 1/4 to 1/5 the size of the smallest geometry can cause fatal defects .

Proper cooling and lubrication systems play vital roles in reducing contamination risks. Eventually, selecting suitable cutting fluids and maintaining proper consumption rates become essential for ultra-precision manufacturing . Different cooling techniques have emerged to address these challenges, including:

Cryogenic cooling

Minimum quantity lubrication

Dry and near-dry machining

High-pressure cooling

Air/vapor/gas cooling systems

The high processing accuracy demands an extremely low working gap, which intensifies contamination concerns through the removal process . Static charge control becomes increasingly important, as reducing static charge during manufacturing leads to substantial reduction in contamination defects .

Modern technology offers sophisticated solutions to address the complex challenges in micro machining operations. Initially, manufacturers must implement comprehensive control systems to maintain precision and reliability.

Advanced thermal management systems fundamentally transform temperature control in micro machining. Active thermal management systems utilizing Peltier elements provide precise temperature control, with two primary variants available :

Passive heat sink systems for basic temperature regulation

Water-cooled heat sinks for higher power dissipation

Modular designs for flexible implementation

Quick temperature stabilization capabilities

These systems maintain consistent operating temperatures, which notably improves tool life and part quality .

Vibration control represents a critical aspect of achieving precise micro machining results. Advanced systems incorporate multiple layers of protection:

Enhanced machine balance mechanisms

Specialized software for chip control

High-performance spindle systems

Rapid tool change capabilities

The implementation of ultra-precision CNC machines with advanced motion control systems enables sub-micron level accuracy . These machines primarily focus on maintaining stability through enhanced vibration control and thermal stabilization features.

Precision measurement solutions essentially form the backbone of quality control in micro machining operations. Modern strain gage systems deliver real-time data monitoring capabilities . These advanced measurement systems excel in:

Capturing detailed stress analysis across various materials

Supporting all phases of testing and measurement

Withstanding extreme conditions while maintaining accuracy

Enabling continuous monitoring and efficient data collection

The integration of high-resolution feedback systems ensures precise control of tool movements . Above all, these measurement solutions provide invaluable data for maintaining long-term integrity and operational excellence in micro machining processes.

Implementing effective maintenance strategies stands as the cornerstone of successful micro machining operations. A well-structured preventive maintenance program can substantially extend equipment lifespan and optimize performance across all operational aspects.

Establishing a systematic calibration schedule fundamentally impacts quality and safety outcomes. A properly maintained calibration schedule helps ensure equipment functions accurately and safely . The frequency of calibration primarily depends on several key factors:

Usage intensity and frequency

Industry-specific requirements

Equipment history and performance

Regulatory compliance needs

Risk assessment outcomes

For optimal results, micro machining equipment requires calibration every three to six months, with more frequent intervals necessary for high-volume production environments . Nevertheless, maintaining detailed documentation of calibration services, including past and future appointments, proves essential for audit compliance .

Tool life monitoring emerges as a critical component in preventing failures and optimizing performance. Modern equipment utilizes sophisticated software to measure and control variables affecting tool longevity . This systematic approach offers numerous advantages:

Real-time detection of tool wear patterns

Predictive maintenance capabilities

Reduction in scrap rates

Enhanced production scheduling

Improved quality control

High-frequency data collection enables precise tool life assessment, essentially eliminating guesswork from maintenance scheduling . Furthermore, automated monitoring systems can detect potential failures before they occur, ultimately reducing downtime and maintaining consistent production quality .

Environmental control protocols play a vital role in maintaining precision and extending equipment life. Proper cooling and lubrication systems prove necessary for reducing friction and controlling cutting temperatures . Different cooling techniques have demonstrated varying degrees of effectiveness:

Minimum quantity lubrication (MQL) has become increasingly favored for ultra-precision manufacturing, balancing sustainability with surface quality requirements . Fundamentally, selecting appropriate cutting fluids and maintaining proper consumption rates directly impacts machining accuracy and tool longevity .

For sustainable operations, manufacturers should consider implementing chlorine-free metalworking fluids, as these substances significantly affect waste management options and disposal costs . Regular monitoring of environmental conditions, coupled with proper fluid maintenance, helps ensure consistent machining quality while minimizing environmental impact.

Micro machining success depends on careful attention to multiple critical factors. Though equipment issues, technical parameters, and environmental challenges present significant hurdles, manufacturers can achieve consistent, high-quality results through proper management strategies.

Advanced thermal control systems, sophisticated vibration management, and precise measurement solutions help address common technical challenges. Regular calibration schedules, combined with tool life monitoring systems, significantly reduce production errors and extend equipment lifespan.

Successful micro machining operations require a balanced approach. Manufacturers must consider equipment capabilities, material properties, and environmental conditions while maintaining strict quality control measures. This comprehensive understanding, paired with proper preventive maintenance, helps ensure reliable, precise results in microscale component production.

The difference between success and failure often lies in attention to detail. Manufacturers who implement robust monitoring systems, maintain proper environmental controls, and follow systematic maintenance protocols position themselves for consistent success in micro machining operations.

Navigation

Navigation

Contact Us

Tel: +86 13417419143

E-mail: [email protected]

Add:

2nd Floor, Building 7, 156 High Tech Industrial Park, Fuyuan 1st Road, Zhancheng Community, Fuhai Street, Baoan District, Shenzhen City, China.